Basic Introduction to Hydraulic Breakers

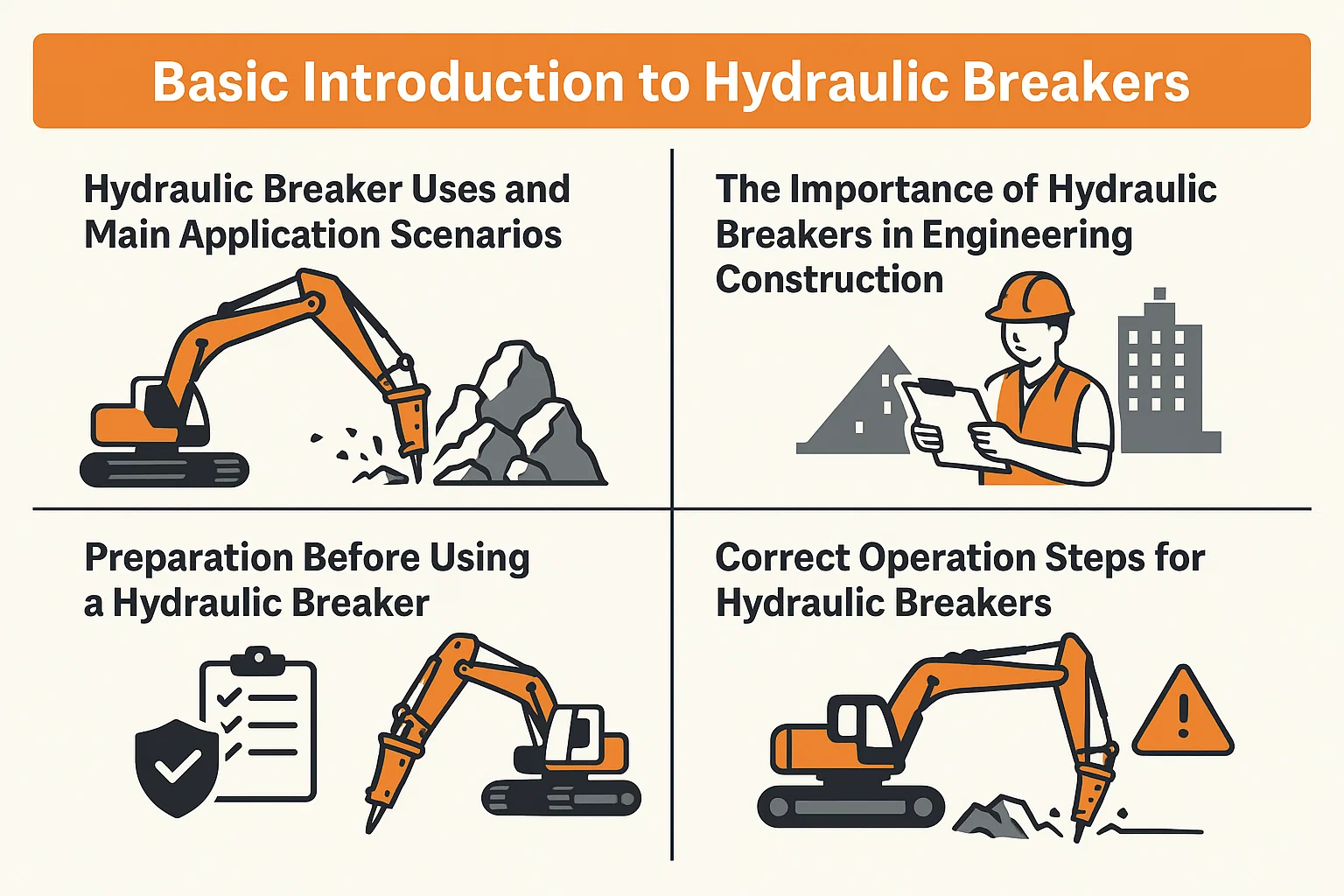

Hydraulic Breaker Uses and Main Application Scenarios

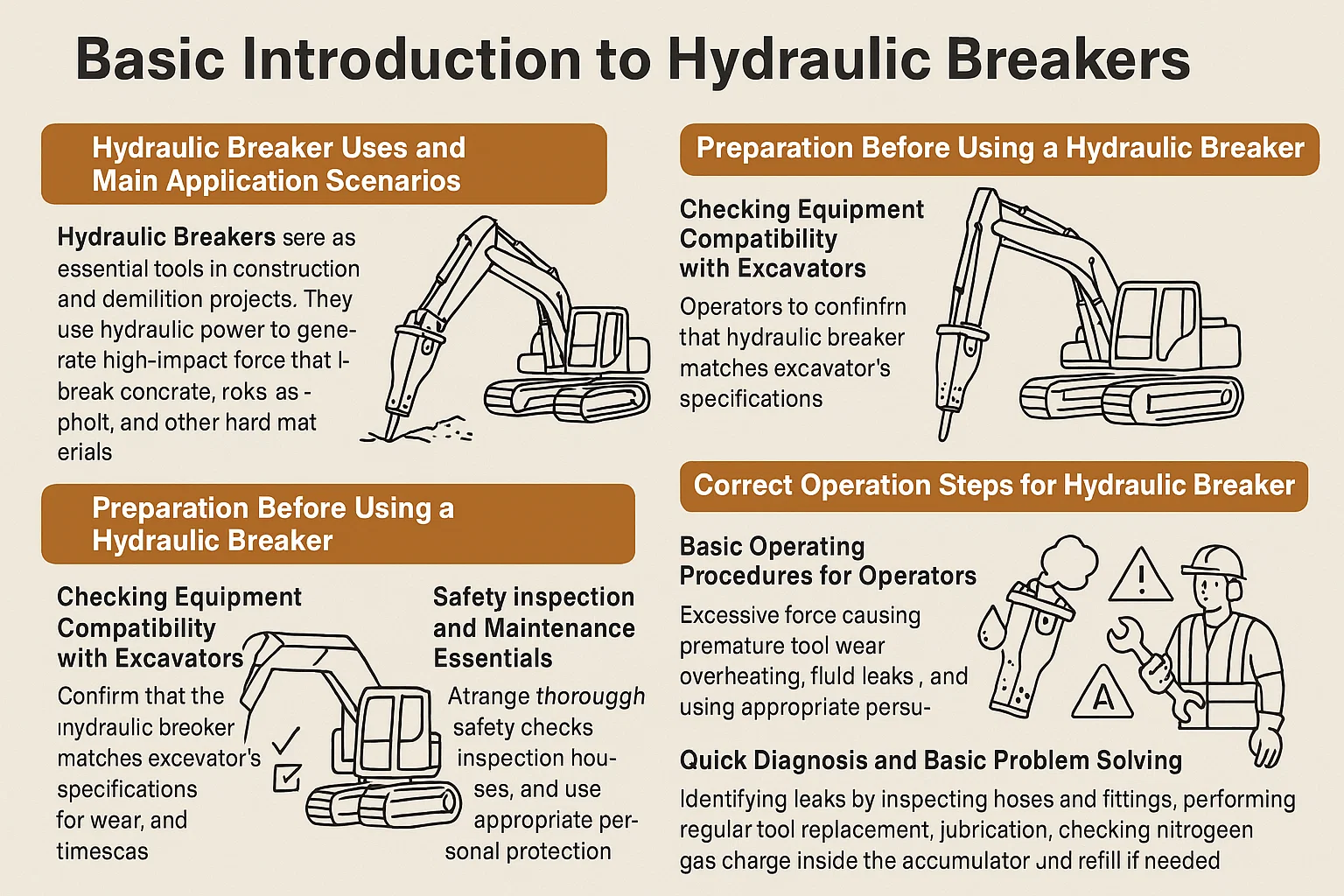

Hydraulic breakers serve as essential tools in construction and demolition projects. They use hydraulic power to generate high-impact force that breaks concrete, rocks, asphalt, and other hard materials. Professionals apply hydraulic breakers in road construction, building demolition, mining, quarrying, and trenching operations. Their ability to deliver consistent and strong impacts allows users to complete heavy-duty tasks efficiently.

The Importance of Hydraulic Breakers in Engineering Construction

Hydraulic breakers improve productivity by reducing manual labor and mechanical stress on equipment. Operators rely on hydraulic breakers to speed up demolition and excavation work while maintaining precision. These tools enhance safety by minimizing dust and vibrations compared to traditional methods. Construction teams use hydraulic breakers to meet tight deadlines and control project costs through efficient material removal.

Preparation Before Using a Hydraulic Breaker

Checking Equipment Compatibility with Excavators

Operators must confirm that the hydraulic breaker matches the excavator’s specifications. Verifying compatibility ensures optimal hydraulic pressure, flow rate, and mounting type. Users should consult the equipment manuals or manufacturers’ guidelines before installation. Proper matching prevents damage to both the breaker and the excavator while guaranteeing efficient energy transfer.

Safety Inspection and Maintenance Essentials

Performing thorough safety checks before each use protects personnel and equipment. Operators should inspect hydraulic hoses, connectors, and the breaker’s tool (chisel or moil point) for wear and damage. Checking hydraulic fluid levels and filters reduces the risk of system failure. Regular maintenance includes lubricating moving parts and tightening loose bolts. A well-maintained hydraulic breaker minimizes breakdowns and enhances work safety.

Correct Operation Steps for Hydraulic Breakers

Basic Operating Procedures for Operators

Operators start by positioning the hydraulic breaker perpendicular to the target surface. They activate the hydraulic flow and control the breaker using the excavator’s joystick or control panel. Maintaining a steady downward force maximizes impact efficiency and prevents tool slippage. Operators must avoid prolonged idling of the breaker to prevent overheating and damage. Following manufacturer guidelines ensures safe and effective use.

Reasonable Site Layout and Important Precautions

Site managers arrange the workspace to ensure clear visibility and safe access around the equipment. Workers should mark hazardous zones and keep bystanders at a safe distance. Clearing loose debris and stabilizing the surface before operation improves breaker performance. Using appropriate personal protective equipment (PPE) such as helmets, gloves, and ear protection reduces injury risks.

Common Problems and Troubleshooting Methods

Frequent Operator Mistakes and Fault Symptoms

Operators may apply excessive force, causing premature tool wear or hydraulic system damage. Overheating results from continuous use without breaks. Faulty hydraulic lines or connectors lead to fluid leaks and loss of pressure. Unusual noises or reduced impact strength indicate internal component wear or damage.

Quick Diagnosis and Basic Problem Solving

Technicians identify leaks by inspecting hoses and fittings for cracks or loose connections. Operators perform regular tool replacement and lubrication to avoid wear-related failures. Cooling breaks and monitoring hydraulic fluid temperature prevent overheating. When impact power drops, users check the nitrogen gas charge inside the breaker’s accumulator and refill if needed.

Tips to Improve Operation Efficiency

How to Extend Equipment Life Through Proper Operation

Operators reduce wear by avoiding excessive pressure and impact duration. Using the breaker only on suitable materials prevents unnecessary damage. Regularly cleaning the breaker and excavator connection points minimizes debris buildup. Scheduled maintenance and timely parts replacement keep the breaker in optimal condition.

Practical Methods to Enhance Breaker Efficiency

Adjusting impact frequency based on material hardness improves energy use. Operators rotate the tool periodically to distribute wear evenly. Using the correct tool type and size for each job increases breaking speed. Efficient scheduling and skilled operation reduce downtime and increase overall productivity.

Recommendations for Selecting the Right Hydraulic Breaker Model

Choosing the Appropriate Model for Different Work Requirements

Selecting the right hydraulic breaker depends on excavator size, material hardness, and project scope. Small models suit light demolition and landscaping, while large breakers handle heavy quarry and construction tasks. Consulting technical specifications and performance charts helps match the breaker with job demands.

Introducing Beilite Products and Building Brand Trust

Beilite offers a range of hydraulic breakers designed for durability and performance. The company manufactures products compatible with various excavator brands and sizes. Beilite’s customer service provides technical support and maintenance advice. Choosing Beilite hydraulic breakers guarantees reliability and professional assistance.

Recap of Key Points and Further Resources

Review of Essential Usage Guidelines for Hydraulic Breakers

Proper use involves equipment compatibility checks, safety inspections, and adherence to operation protocols. Efficient site layout and PPE use ensure safe working conditions. Operators must follow maintenance schedules and troubleshooting methods to avoid breakdowns. Selecting the right breaker model aligns with specific project requirements.

Additional Learning and Support Channels

Users can access detailed tutorials and technical guides on the Beilite official website. The company provides direct consultation and after-sales support. Online forums and training videos supplement user knowledge. Staying informed about updates and best practices enhances operational success.

Frequently Asked Questions About Hydraulic Breakers

What Are the Main Safety Precautions When Using a Hydraulic Breaker?

Operators must always wear PPE, check equipment integrity before use, and maintain safe distances from bystanders. Regular hydraulic system inspections and avoiding overuse prevent accidents.

How Often Should I Perform Maintenance on a Hydraulic Breaker?

Perform daily visual inspections, weekly lubrication, and scheduled professional maintenance based on operating hours. Timely upkeep extends equipment lifespan and prevents costly repairs.

How Can I Improve the Efficiency of My Hydraulic Breaker?

Adjust impact settings to match material hardness, use the correct tool for each task, and avoid continuous operation without breaks. Proper site preparation also improves performance.

How Do I Choose the Best Hydraulic Breaker Model for My Excavator?

Review your excavator’s specifications, material types, and project size. Consult manufacturer guidelines and experts like Beilite for model recommendations suited to your needs.