The hydraulic breaker, also known as a hydraulic hammer, plays a key role in construction, mining, and demolition projects. This powerful tool uses hydraulic power to break hard materials like rocks and concrete. Operators often install Hydraulic Breakers on excavators or backhoes to complete heavy-duty tasks efficiently.

What Is a Hydraulic Breaker?

The hydraulic breaker is a powerful percussion hammer attached to excavators. Operators use it to break rocks, asphalt, and concrete. This equipment depends on hydraulic pressure to deliver strong impact energy directly to the target surface. The hydraulic breaker increases productivity and helps complete tough tasks efficiently.

Basic Structure of a Hydraulic Breaker

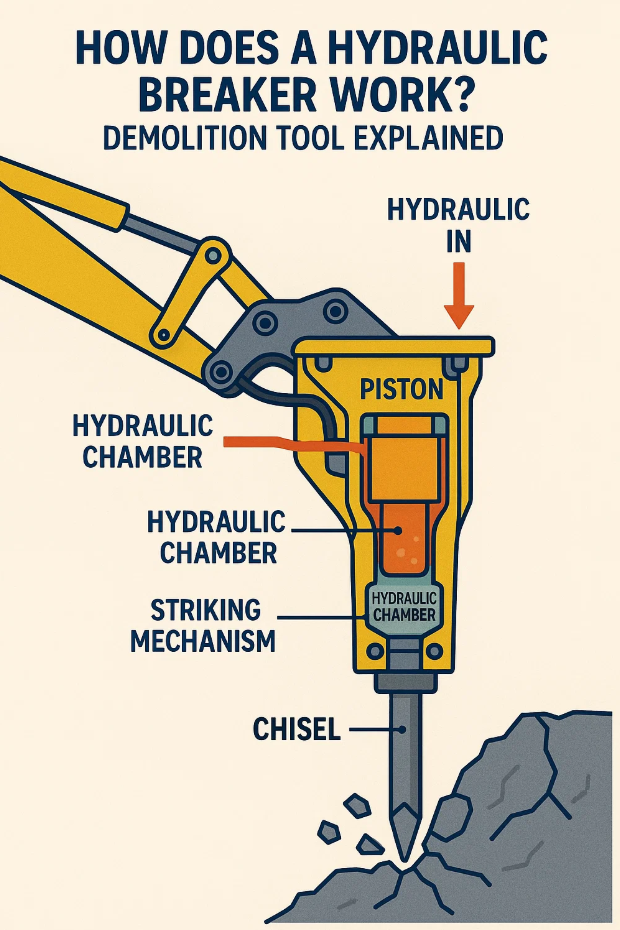

Manufacturers design the hydraulic breaker structure to handle extreme forces. The breaker mainly consists of the cylinder, piston, chisel, nitrogen chamber, and valve system. The sturdy design allows the hydraulic breaker to transfer hydraulic power into mechanical impact with minimal energy loss. The reliable hydraulic hammer structure helps the tool operate consistently under pressure.

Working Principle of a Hydraulic Breaker

The hydraulic breaker working principle focuses on hydraulic oil pressure and gas energy. The excavator’s hydraulic pump supplies pressurized oil to the breaker. The hydraulic oil moves the piston inside the cylinder. When the piston moves downward rapidly, it strikes the chisel with high force. The nitrogen gas in the upper chamber helps absorb recoil and increases the impact power. This continuous cycle of piston movement and chisel impact allows the hydraulic breaker to break hard materials effectively.

Key Components of a Hydraulic Breaker

Each hydraulic breaker component performs an essential function during operation. The main components include:

- Cylinder: Guides the piston and converts hydraulic pressure into linear motion.

- Piston: Transfers force directly to the chisel.

- Chisel: Breaks rocks, concrete, or other materials.

- Nitrogen Chamber: Stores nitrogen gas to assist piston movement and absorb recoil.

- Valve System: Controls oil flow and piston direction.

These hydraulic breaker components work together to ensure stable and powerful operation.

Hydraulic Breaker Application in Different Industries

The hydraulic breaker application covers various industries. Construction workers use it to demolish buildings and remove concrete foundations. Mining operators rely on it to break large rocks and extract minerals. Road maintenance teams apply it to remove old pavements and repair highways. The excavator hydraulic breaker also supports trenching, tunneling, and quarrying activities. Its wide application helps companies improve work efficiency and reduce manual labor.

How to Operate a Hydraulic Breaker Efficiently

Operators must follow correct procedures to achieve efficient hydraulic breaker operation. First, they select the proper hydraulic flow rate based on the breaker’s requirements. Second, they position the chisel correctly on the target surface. Third, they avoid using the breaker at an angle to prevent chisel damage. Fourth, they limit continuous hammering time to prevent overheating. Fifth, they check hydraulic oil levels and system pressure before each use. These steps help extend the lifespan of the hydraulic hammer and maintain high productivity.

Factors Affecting Hydraulic Breaker Performance

Several factors influence hydraulic breaker performance. Hydraulic oil quality directly impacts breaker efficiency. Poor oil can damage internal parts and reduce impact power. Correct hydraulic pressure ensures optimal piston movement. Incorrect pressure can cause weak striking force. Chisel condition also affects performance. A dull or damaged chisel reduces breaking efficiency. Regular system checks and proper matching with the excavator can improve the hydraulic breaker working principle and output.

Importance of Hydraulic Breaker Maintenance

Regular hydraulic breaker maintenance ensures safe and efficient operation. Operators must inspect bolts, hoses, and pins frequently. Loose parts can cause damage or failure. They should grease the tool regularly to reduce wear between moving parts. Checking nitrogen pressure helps maintain impact power. Replacing worn chisels and seals prevents performance drops. Careful maintenance extends the service life of the hydraulic breaker and improves project efficiency.

Common Problems and Troubleshooting Methods

Operators may face common hydraulic breaker operation problems. Oil leaks often occur at hose connections. Tightening the fittings or replacing damaged hoses can solve this issue. Weak impact force usually results from low hydraulic pressure or low nitrogen levels. Increasing oil pressure or refilling nitrogen can restore power. Abnormal noise may come from loose bolts or damaged internal parts. Inspecting and repairing these parts can eliminate noise. Frequent equipment inspections help identify problems early and reduce downtime.

How to Select the Right Hydraulic Breaker

Choosing the correct breaker improves hydraulic breaker application results. Buyers should consider the excavator’s weight and hydraulic capacity. The breaker must match the carrier’s oil flow and pressure. They must also consider the material hardness and project requirements. For light demolition, a smaller breaker can meet the need. For rock breaking, a larger breaker with high impact energy performs better. Buyers can review manufacturer specifications to ensure the hydraulic breaker selection fits their tasks.

Summary of Key Points

The hydraulic breaker helps many industries complete tough breaking jobs efficiently. Operators must understand its structure, working principle, and correct operation. Regular maintenance and proper breaker selection ensure stable performance. This knowledge helps teams improve work quality and reduce equipment failure.

Contact Beilite for Reliable Hydraulic Breakers

Beilite offers a full range of reliable hydraulic breakers to support construction, mining, and roadwork. Contact our team to find the best solution for your project needs. We provide durable hydraulic hammers with strong impact power and easy maintenance.

Frequently Asked Questions

What is the main function of a hydraulic breaker?

The hydraulic breaker uses hydraulic pressure to break hard materials like rocks, concrete, and asphalt. Operators install it on excavators to complete demolition, mining, and road repair tasks efficiently.

How does the nitrogen chamber help the hydraulic breaker?

The nitrogen chamber stores gas pressure that supports the piston movement. It absorbs recoil and increases impact force, helping the hydraulic breaker deliver strong blows with each strike.

How can operators prevent hydraulic breaker damage?

Operators can prevent damage by using the hydraulic breaker correctly. They must position the chisel properly, avoid hammering at an angle, limit continuous operation time, and check hydraulic oil levels regularly.

How often should hydraulic breaker maintenance take place?

Operators should inspect the hydraulic breaker daily before use. They need to grease the tool regularly, check nitrogen pressure, and tighten bolts. Performing scheduled maintenance every few hundred hours keeps the equipment in good condition.