he hydraulic breaker hammer plays a vital role in many industries. People use this powerful tool to break rocks, demolish concrete, and handle challenging excavation tasks. Understanding this equipment helps users make informed decisions and improves work efficiency. This guide offers essential knowledge to help users explore hydraulic breaker hammer applications, types, selection tips, and maintenance practices.

What is a Hydraulic Breaker Hammer and Where Does It Apply?

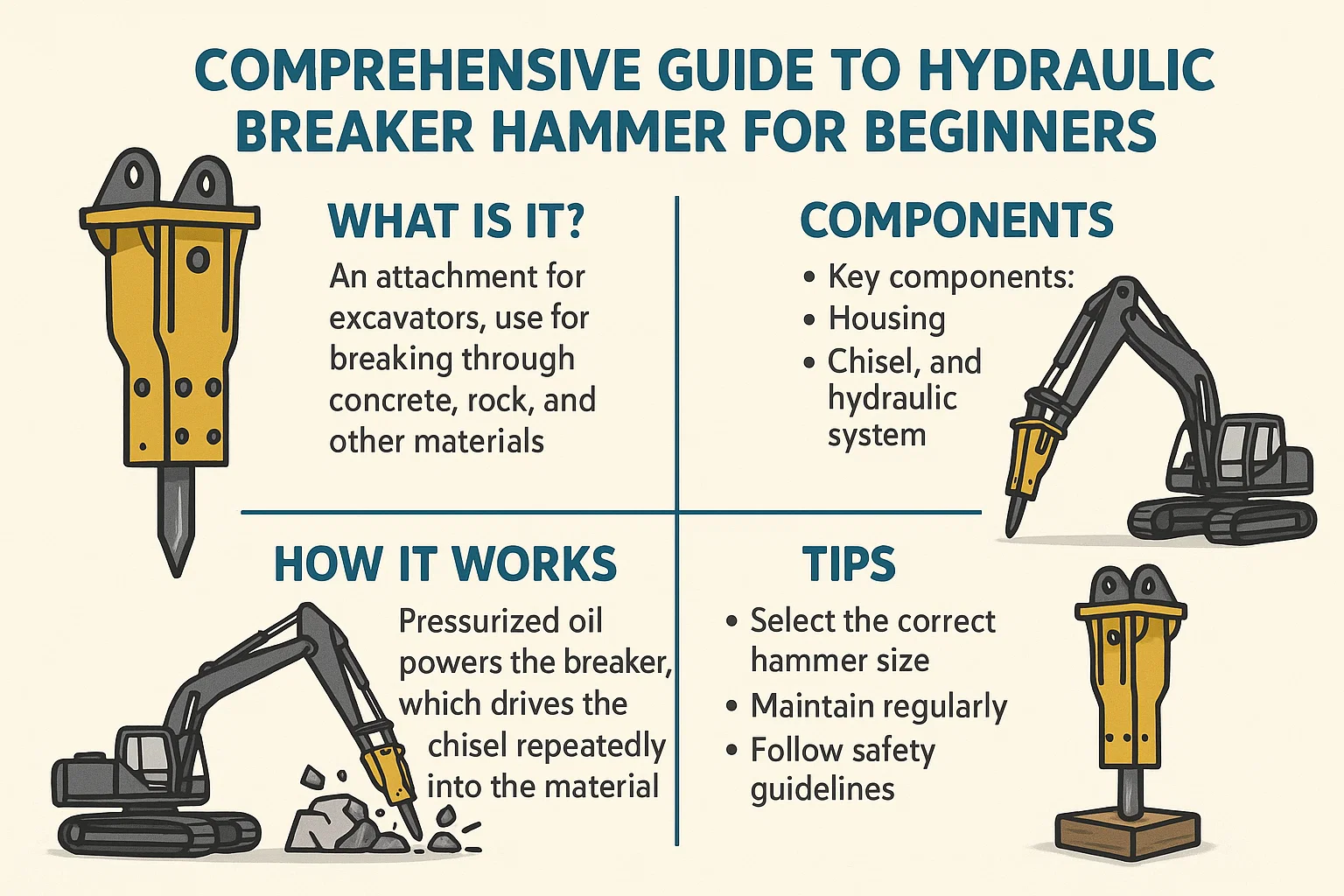

A hydraulic breaker hammer uses hydraulic pressure to deliver high-impact blows. People install it on excavators to complete heavy-duty tasks. Construction workers, miners, and demolition teams often rely on this tool to handle tough materials quickly and efficiently. Many projects require a hydraulic breaker hammer to break concrete, rocks, and road surfaces.

The Hydraulic Breakers offer excellent power and versatility. Professionals apply them in road construction, mining operations, foundation work, and urban infrastructure projects. The hydraulic breaker hammer application covers a wide range of heavy industries. Workers appreciate its efficiency and adaptability in challenging environments.

Exploring Different Types of Hydraulic Breaker Hammer

The market offers various hydraulic breaker hammer types to suit different machines and work conditions. People can choose light-duty, medium-duty, or heavy-duty models. Light-duty breakers handle smaller tasks like breaking sidewalks or bricks. Medium-duty breakers work well for road repairs and trenching. Heavy-duty breakers can demolish large concrete structures and massive rocks.

Each hydraulic breaker hammer matches a specific excavator size. Operators must select a breaker that fits their excavator’s hydraulic capacity and weight. Choosing the right hydraulic breaker for excavator ensures safe and efficient operations. Selecting the wrong size can damage both the excavator and the breaker.

How to Choose the Right Hydraulic Breaker Hammer for Your Project

Users must understand how to choose a hydraulic breaker hammer for their specific job. They need to consider the work environment, material hardness, and required impact force. Selecting the best hydraulic breaker for excavator depends on proper equipment matching. Operators should review the breaker’s weight, oil flow requirement, and pressure settings.

Choosing the right breaker prevents downtime and extends equipment life. Many professionals ask, “How to choose hydraulic breaker hammer?” They examine their excavator’s capacity, jobsite conditions, and daily operating hours. A well-matched breaker maximizes productivity and minimizes repair costs. Operators often search for the best hydraulic breaker for excavator to handle tough jobs safely.

Common Mistakes and Best Practices When Using a Hydraulic Breaker Hammer

Operators sometimes make mistakes when using a hydraulic breaker hammer. Improper use leads to equipment damage and increased maintenance costs. People may apply the breaker continuously without breaks, which can cause overheating. Some users operate the breaker at the wrong angle, creating stress on the equipment.

Following proper techniques prevents these problems. Operators should always use the breaker vertically and avoid blank firing. Professionals recommend stopping the operation if the material does not break quickly. They also advise operators to regularly check the breaker’s fasteners and bushings. By following these hydraulic breaker hammer tips, users can achieve better results and reduce risks.

Avoiding the most common hydraulic breaker hammer mistakes protects both the tool and the machine. Careful handling, regular inspections, and proper lubrication improve equipment longevity. Operators benefit from focusing on safety and applying correct operating procedures every day.

Maintenance Tips to Extend Hydraulic Breaker Hammer Lifespan

Proper maintenance keeps a hydraulic breaker hammer in excellent condition. Daily inspections help detect wear and prevent unexpected failures. Operators should regularly grease the tool bushing and check for leaks. Cleaning the breaker after each use prevents debris from damaging internal parts.

Following hydraulic breaker maintenance schedules ensures reliable performance. Operators should monitor nitrogen pressure, replace worn parts on time, and use the correct hydraulic oil. A well-maintained breaker works efficiently and lasts longer. People who follow simple maintenance steps extend the hydraulic breaker lifespan and reduce operational costs.

Proper storage also supports longevity. Operators should store the breaker in dry, clean areas to prevent rust and corrosion. Regular maintenance increases safety and minimizes unplanned downtime.

Current Industry Trends and New Hydraulic Breaker Hammer Technologies

The hydraulic breaker hammer industry continues to evolve. Manufacturers develop more durable and energy-efficient models to meet modern demands. Many projects now require breakers that offer higher power with lower vibration. These improvements help operators work comfortably and safely.

The latest hydraulic breaker hammer technology includes noise-reducing features and better energy recovery systems. These advances reduce fuel consumption and improve breaker efficiency. Manufacturers also focus on creating lightweight designs without sacrificing power.

The hydraulic breaker market trends show increasing demand for environmentally friendly equipment. Companies now offer breakers that produce less noise and lower emissions. Many users prefer these models for urban projects and sensitive environments.

How to Select a Reliable Hydraulic Breaker Hammer Supplier

Choosing a trusted supplier helps users obtain high-quality hydraulic breaker hammer products. Buyers should evaluate the manufacturer’s experience, product certifications, and service support. Reliable suppliers provide comprehensive after-sales assistance and fast spare parts delivery.

When selecting a supplier, buyers should review product quality and customer feedback. A reliable hydraulic breaker supplier offers detailed product information, transparent pricing, and strong technical support. Partnering with an established manufacturer guarantees long-term value.

Working with a reputable hydraulic breaker manufacturer ensures product consistency and timely service. Customers gain confidence when they choose suppliers who offer well-tested and field-proven equipment.

If you want expert guidance and high-performance hydraulic breaker hammer solutions, Beilite welcomes your inquiries. Our team provides professional advice to help you choose the best product for your project.

Contact Beilite today to discover the most suitable hydraulic breaker hammer for your needs. Our experts are ready to assist you with product selection and technical support.

Frequently Asked Questions About Hydraulic Breaker Hammer

1. How do I know which hydraulic breaker hammer fits my excavator?

You should check your excavator’s hydraulic flow, operating pressure, and machine weight. Matching these parameters helps you select the right hydraulic breaker for excavator and ensures efficient, safe operation.

2. What is the best way to maintain a hydraulic breaker hammer?

Regularly grease the tool bushing, monitor nitrogen pressure, inspect for oil leaks, and clean the breaker after each use. Following a strict hydraulic breaker maintenance routine extends the hydraulic breaker lifespan and improves reliability.

3. What are the most common mistakes when using a hydraulic breaker hammer?

Common mistakes include continuous operation without breaks, incorrect working angles, and blank firing. Operators should follow proper hydraulic breaker hammer tips to prevent equipment damage and ensure safety.

4. What are the key trends in the hydraulic breaker hammer industry?

The hydraulic breaker hammer technology now focuses on noise reduction, energy efficiency, and lightweight designs. The hydraulic breaker market trends highlight growing demand for environmentally friendly, high-performance breakers.