Many operators ask, will a hydraulic hammer break rock? The answer is yes. A properly matched and correctly operated hydraulic hammer can break rock efficiently. Professionals across industries rely on this equipment to fracture solid rock surfaces during excavation, construction, and mining tasks.

Understanding Hydraulic Hammers

A hydraulic hammer, also called a hydraulic breaker, uses hydraulic pressure to drive a chisel into hard surfaces. Operators attach this tool to excavators or backhoes. The hammer delivers consistent impact force, which breaks down tough materials. Users commonly break rock with hydraulic breaker units in areas with compact geology or reinforced ground.

How Hydraulic Hammers Break Rock

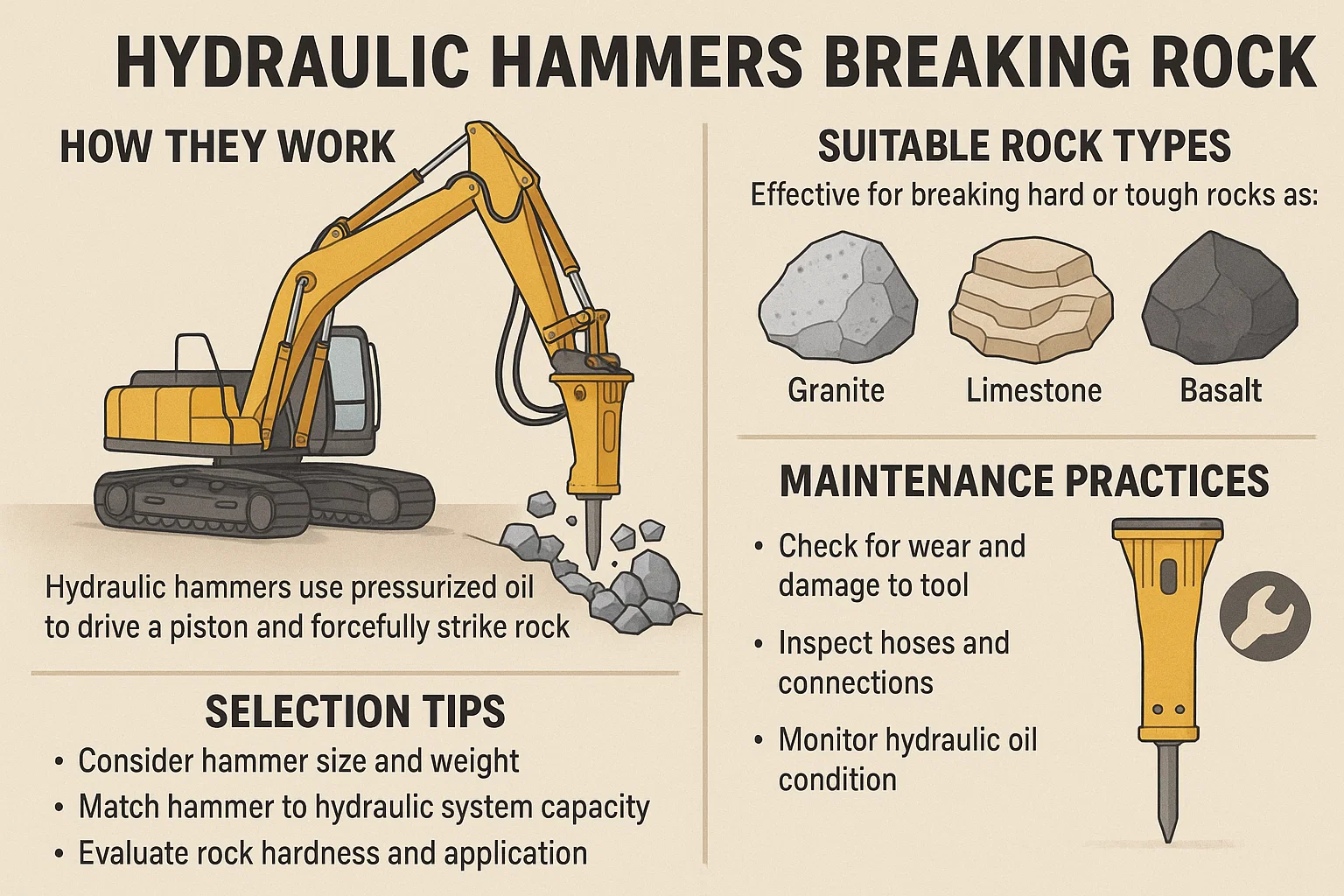

Hydraulic hammers generate powerful blows through an internal piston. The piston strikes the tool bit repeatedly, transmitting high-impact energy into the rock. This energy causes cracks to form and eventually splits the rock apart. Operators break rock using hydraulic hammer tools by applying steady force and adjusting the angle of attack as needed.

Rock Types Suitable for Hydraulic Hammer Use

Users often wonder, can a hydraulic breaker break rock regardless of type? Hydraulic hammers can tackle several rock types, including:

- Granite

- Basalt

- Limestone

- Sandstone

- Shale

The tool’s effectiveness depends on rock hardness, density, and existing fractures. For very dense materials, users should select a heavier hammer model and apply methodical technique.

Key Components That Ensure Rock Breaking Efficiency

To ensure efficient rock breaking with hydraulic equipment, the system relies on several critical components:

- Hydraulic power unit – Drives fluid to generate energy.

- Chisel or moil point – Transfers force directly to rock.

- Accumulator – Regulates pressure and reduces stress.

- Mounting bracket – Keeps the breaker steady.

Operators must inspect these parts regularly. Worn tools or insufficient pressure can reduce effectiveness.

Best Practices When Using Hydraulic Hammers on Rock

Operators can improve results by following best practices:

- Position the chisel correctly on the rock face.

- Apply constant downward pressure from the carrier.

- Limit blank firing by keeping the chisel in contact with rock.

- Use proper tool bits for specific rock types.

These practices help maintain efficiency and protect the equipment from unnecessary wear.

Common Applications in Rock Demolition

Construction teams often use hydraulic hammers to break rock in urban areas, where blasting is not permitted. Common applications include:

- Trenching through rock layers

- Removing boulders from construction sites

- Breaking up rock during road construction

- عمليات التعدين واستغلال المحاجر

Contractors rely on القواطع الهيدروليكية for these tasks due to their safety and precision in confined spaces.

Selecting the Right Hydraulic Hammer for Rock

Choosing the right hammer determines whether you can break rock using hydraulic hammer tools effectively. Consider these factors:

- Carrier weight and hydraulic capacity

- Hammer weight and impact energy

- Application requirements (depth, frequency, rock hardness)

Manufacturers offer various models suited for different rock densities and job conditions.

Maintenance Tips to Improve Rock Breaking Performance

Maintenance extends tool life and improves performance when breaking rock:

- Check hydraulic oil regularly and maintain correct levels.

- Inspect chisel tools for wear and replace them when needed.

- Keep bushings lubricated to reduce friction and prevent damage.

- Clean the hammer after each use to remove dust and debris.

Proper upkeep ensures the hydraulic hammer remains powerful and consistent.

Why Choose Hydraulic Hammers over Other Rock Breaking Tools

Compared to drilling or blasting, hydraulic hammers offer several advantages:

- Precise control of impact location

- Lower risk to nearby structures

- No need for explosives or permits

- Less noise and vibration

Operators prefer them for safe, reliable rock demolition, especially in populated or restricted environments.

Summary of Rock Breaking with Hydraulic Hammers

Professionals frequently ask, is hydraulic hammer suitable for breaking rock? Field experience confirms that hydraulic hammers deliver strong performance in rock demolition tasks. They use high-impact energy to fracture rock efficiently. When matched with the right carrier and maintained properly, the hammer handles a wide range of rock types. Contractors around the world use these tools daily to break rock in construction and excavation.

Contact Our Experts

If you need reliable tools to break rock on your job site, our team can help you choose the right hydraulic hammer. Contact us today to speak with a specialist who can guide you based on your project needs.

الأسئلة المتداولة

1. Can a hydraulic hammer break hard rock like granite?

Yes. A high-powered hydraulic hammer with sufficient impact energy can break granite. Operators should use heavier equipment and high-strength chisels for dense materials like granite or basalt.

2. How do I choose the right hydraulic breaker for rock?

Match the breaker to your carrier’s weight and hydraulic output. Select a model with the proper impact energy for the rock type and application. If unsure, consult the manufacturer for recommendations.

3. How often should I maintain my hydraulic hammer?

Perform daily visual checks and regular maintenance after every 100 to 200 hours of use. Inspect tool bits, hydraulic oil, and bushings to ensure safe and efficient operation.

4. What size excavator do I need for rock demolition with a hydraulic breaker?

The size depends on the breaker’s weight and job requirements. Light demolition may only require a 6-ton excavator, while heavy-duty rock removal often needs 20 tons or more for stable operation.